Target Cascading Tool (TCT) is a powerful software solution that facilitates the process of chassis systems and components specification and enables manufacturers to optimize their product development process across different stages of the v-cycle. It does this by providing a comprehensive user interface for the definition of vehicle performance targets and utilizing an integrated vehicle model as part of an automatic optimization.

Why the TCT tool improves efficiency in vehicle dynamics teams?

Target cascading can be considered a tedious process consisting of several steps that are difficult to integrate. The TCT eases this activity by providing a set of integrated functions that include correlation of objective and subjective data, target setting, target cascading via simulation, and analysis of results.

For any project start-up, and especially in cases where there is no previous reference, the TCT is able to generate a set of specifications in one click with only a few vehicle targets and vehicle body characteristics.

The vehicle model and its parameter configurations can be saved and linked to a project together with the KPI results so that reporting and comparison between set-ups and against targets is quick and easy. As an example of application, there are three common use cases where the tool becomes a great asset:

During the definition of a new concept vehicle

TCT enables users to quickly define a starting set-up of specs and to identify potential issues and challenges early in the development process, reducing the need for costly and time-consuming physical testing. The user can also complete the virtual cycle from target setting to component specification in less than 8h, including full optimization of springs, dampers, and suspension kinematics and compliance characteristics.

During tuning activities

The tool can provide inputs to the tuning engineer, by quantifying the impact of parts specification changes in both handling and ride comfort at once, in less than a few seconds.

During the definition of hardpoints working in parallel with other Multibody-system (MBS) simulation tools

The tool includes a hardpoint definition module that helps engineers to trace changes in hardpoint locations and have control on the changes by taking into consideration packaging and kinematics constraint to adapt specific aspects of the suspension kinematics and compliance while minimizing the impact on others.

What is different in the TCT tool?

The TCT tool is unique in providing a set of functionalities that enable to complete a cycle of virtual development. The target setting module makes it possible to incorporate your own benchmark data from a simple Excel file and set up correlation models and target ranges to be used during the optimization of the model parameters.

The solution also incorporates a 15 DOG model developed by IDIADA, which is also configurable for independent suspension of rigid axles and has been correlated to multibody simulation, ensuring a good performance for both handling and ride-comfort.

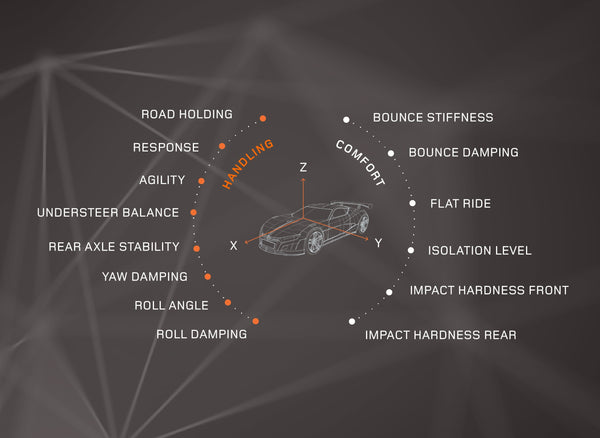

Finally, the TCT workflow guarantees that both ride comfort and handling aspects are considered at all times without any additional effort in model or test cases preparation. To do this, a selection of test cases is pre-configured and run in every simulation or iteration during the optimization. This test cases cover steady-state lateral dynamics, lateral transient dynamics, impact hardness and primary ride on deterministic inputs, and secondary ride on a non-deterministic input. This way, the user gets all KPIs calculations at once and can justify the compromised solution that balances handling and comfort.

From concept definition to tuning activities, the TCT tool is a valuable companion in chassis and vehicle dynamics activities, that speeds up the process to meet the current development programmes where the time-to market is getting smaller and smaller and the agility to make well-justified decisions is a must.